This service may collect data about your activities. Please inform yourself about the service and agree to the use of YouTube Video.

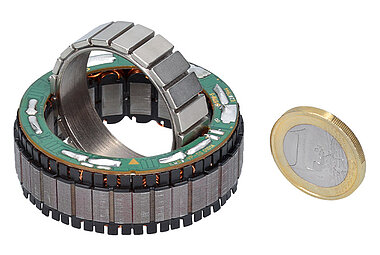

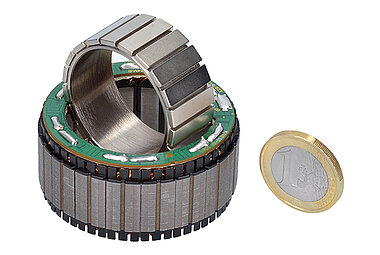

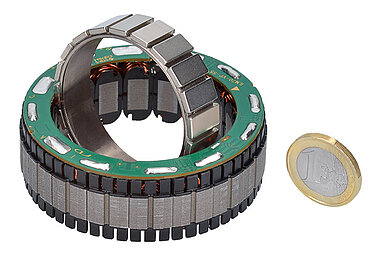

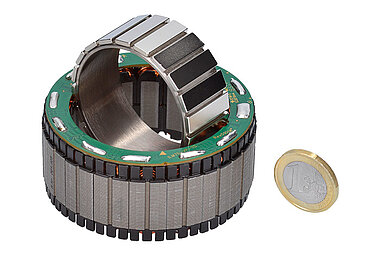

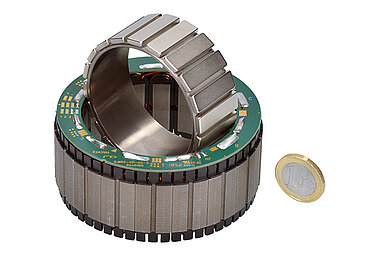

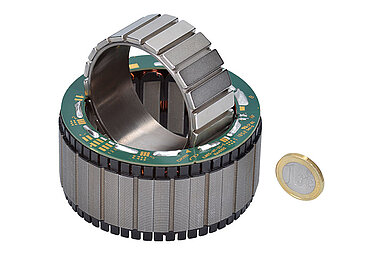

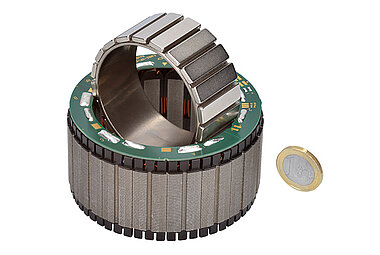

New frameless ILM-E series Cost-efficient drive technology for the most challenging applications!

The new TQ-ILM-E series offers torque density low weight for the most challenging applications. Whether in automation, medical technology, mechanical engineering, aviation and robotics, they enable designers to overcome technological boundaries.

The new ILM-E series from TQ-RoboDrive are a cost-effective alternative to our premium ILM series and offers the essential TQ-RoboDrive performance at an excellent price/performance ratio. Particularly noteworthy is that the ILM-E series has the same torque per kilogram as the Premium ILM series.

In addition, TQ-RoboDrive offers customized frameless motors based on the ILM-E, which can be adapted to the individual customer requirements via the number of windings and the lengths. This means that the performance of the motors can be adapted to your personal needs.

TQ-ILM-E: high performance at a competitive price

The ILM (Innen Läufer Motor) is based on the development of the DLR (German Aerospace Center). In order to be able to produce this powerful drive more cost-effectively, TQ has developed the ILM-E series. To this end, much of the ILM's manual manufacturing was automated. This enables a better price-performance ratio with similar product properties as the ILM.

The new ILM-E series from TQ-RoboDrive offers:

- Frameless construction for high design flexibility

- Excellent torque density at an attractive price-performance ratio

- Low thermal losses thanks to high copper fill-factor

- Lightweight and compact

- Smallest and lightest solution compared to competitors

- Spacious hollow shafts for additional functions in the same installation space

- Flexibly adaptable to customer requirements

- 100% Made in Germany

TQ-ILM-E: indispensable for industry application

The diverse applications range from handling, assembly automation, industrial robots, cobots, to power tools, industrial trucks, industrial equipment, measuring machines, etc.

- Thanks to high torques, even larger loads can be moved dynamically

- The light and compact drive allows correspondingly light and compact devices to be developed

- Low losses allow a permanently high torque

- Additional functions can be integrated in the hollow shaft without taking up more space

- Due to the flexible design of the ILM-E, customer-specific concepts can be realized more quickly

TQ-ILM-E: optimal drive for medical technology

The new drive is indispensable in laboratory equipment such as centrifuges and mixers, but also in surgical robots, surgical tables, microscopes and – since it's clinically pure - in dialysis machines, in X-ray machines, CTs, but also in exoskeletons, etc.

- Thanks to high torque, the downstream gear reduction can be reduced, which makes it pleasantly quiet for staff and patients

- Due to low losses, the device surface remains relative cool, even at high loads

- Small dimensions enable compact, portable devices with high power output

- The flexible design of the drive allows customer-specific concepts to be implemented more quickly

The TQ Group's ILM-E frameless motor becoming the heart of the world's first truly modular industrial robot

The TQ-Group has been promoting innovative start-ups for many years and supports them with development know-how, marketing campaigns and attractive purchase prices for TQ components. These companies also include Kea Robotics, a team of 13 robot experts located in Munich. Kea developed the world's first fully-fledged modular industrial robot - the robot's modules are moved exclusively with ILM-E servo motors from TQ.

Learn more about the Kea Robotics Success Story now