Request more info

Do you have any questions about our services? We are looking forward to your inquiry and will respond quickly. Here you will find an overview of how to reach us.

Comprehensive inspection and testing, along with quality monitoring throughout the entire process, enable us to guarantee the best quality and functionality for our customers’ components – always taking into account the ideal inspection depth and a balanced cost-benefit ratio. In collaboration with you, we devlop the optimal design for testability, in which testing aspects (also known as DFX aspects) are defined early on in the product development process.

In doing so, we consider the specifics of the respective industry, as well as the annual volume, product life cycles and the complexity of your modules. This helps you save costs and will later avoid problems during production.

All test procedures are of course recorded in our traceability system.

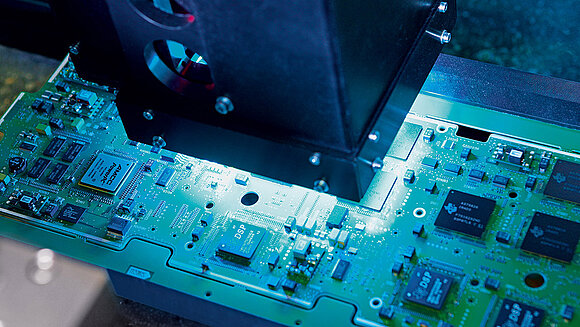

AOI (automated optical inspection) describes systems that use image processing to detect soldering errors on components. The process is a further development of machine vision applications.

We offer automatic optical inspection for Solder Paste Inspection (SPI), SMD assembly and soldering, and THT.

By means of manual and automatic X-ray inspection, solder joints, components and printed circuit boards are examined. The checks can be carried out according to your needs - during series transition, randomly thoughout series production or even for the complete series. High-resolution X-ray systems with tomography function enable optimum defect detection and analysis.

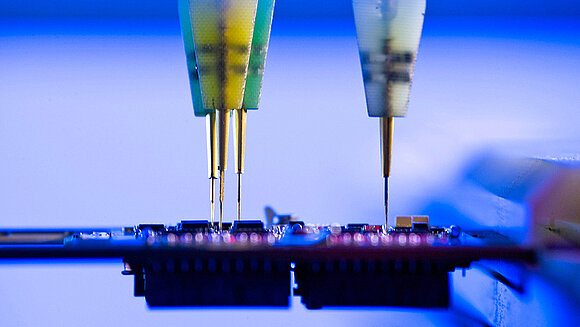

Checks to ensure proper processing and in some cases test the parameters and functions of the components. The FPT does not require product-specific test adapters and is essentially equivalent to the MDA (Manufacturing Defect Analyzer) which detects manufacturing defects.

Seven of these test systems at different locations, along with other test procedures, ensure high processing quality at TQ. We use the powerful FPT systems by the manufacturer SPEA, which ensure precise measurements integrated in a multi-process platform and now also enable an "optical test" of LEDS.

This testing method contacts every accessible circuit node on the test object via a needle bed. This happens on our systems with approx. 500 measurements per second at up to 2000 measuring points.

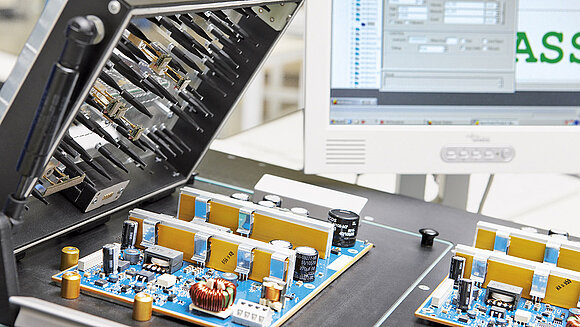

We use this to test the correct assembly of components and, as far as possible, their characteristic values. The test also examines component functionalities for complex digital components. The In-Circuit Test also includes the onboard programming of memory devices. 20 of these powerful test systems at different locations, along with other test procedures, ensure high processing quality at TQ.

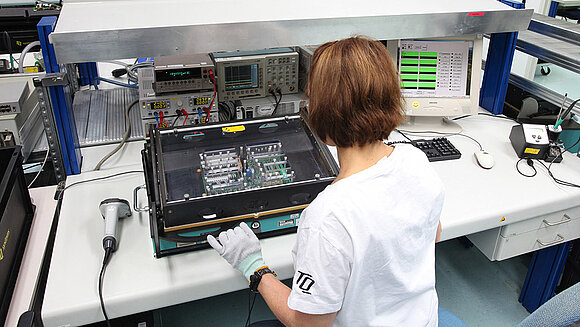

The functional test - as the name suggests - focuses on the functionality of the DUT and is created in close coordination with the development department (TQ-internal or customer).

Our development team has designed well over 100 TQ standard functional test systems which we use where possible.

Apart from that, it is common practice at TQ to test the components by means of functional test systems provided by our customers.

The boundary-scan test can be used as an independent test procedure, but can also be integrated as a component of other test procedures, e.g. the functional test. A BST is preferably used on assemblies with high component packing densities.

In the boundary-scan test we distinguish between:

A module is tested with the aid of "electronic nails". These are located at the pins of the boundary-scan-capable components via which digital signals are applied and measured. Circuits can also be programmed by means of the BST. In addition, several modules can be tested or programmed simultaneously in the BST.

Depending on our customers' demands and wishes, we carry out burn-in and run-in tests for additional quality assurance. These can be performed statically or dynamically (i.e. with constant or variable temperatures), as well as actively or passively (i.e. with or without operation of the module), depending on the requirements.

Burn-in and run-in testing can identify weak points and batch problems, reduce early failures and increase reliability in the field.

The Highly Accelerated Life Test (HALT) puts assemblies and devices under increased thermal and mechanical stress subjecting them to extreme temperatures, strong temperature gradients and random vibration in order to identify and optimize weak points in the design and in the components used during development and product qualification.

The load limits (destruction limits) obtained through the HALT can then be used in a series suspended by a defined safety margin to carry out production-accompanying HASS tests (Highly Accelerated Stress Screening) which detect batch problems with individual components or processing defects.