Request more info

Do you have any questions about our services? We are looking forward to your inquiry and and will respond quickly. Here's an overview of how to reach us.

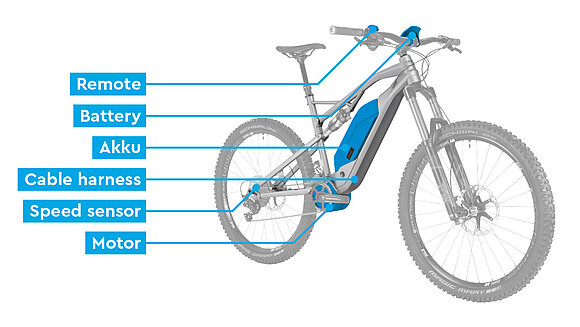

We are your innovative and comprehensive development partner. Whether electronics, software, layout, mechanics or system development - TQ supports you in the development of your products from the product idea to the realization of the series product and product maintenance.

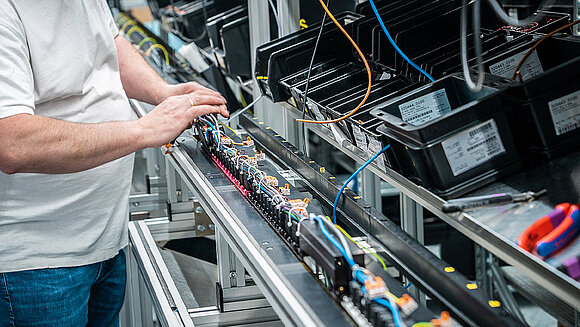

As an E²MS systems provider (Electronic Engineering & Manufacturing Services), we can help you design printed circuit boards, components and complete units to meet every need and requirement. Having many years of experience and an extensive know-how in a wide range of industries, our development team will always find suitable and successful solutions for your needs.

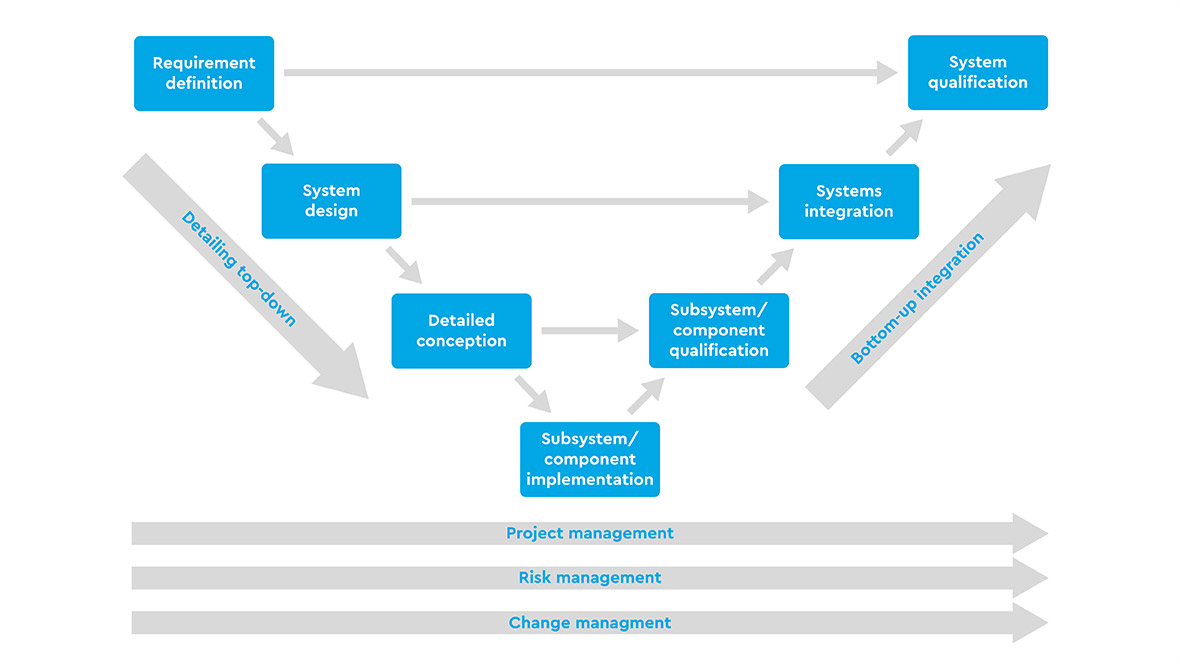

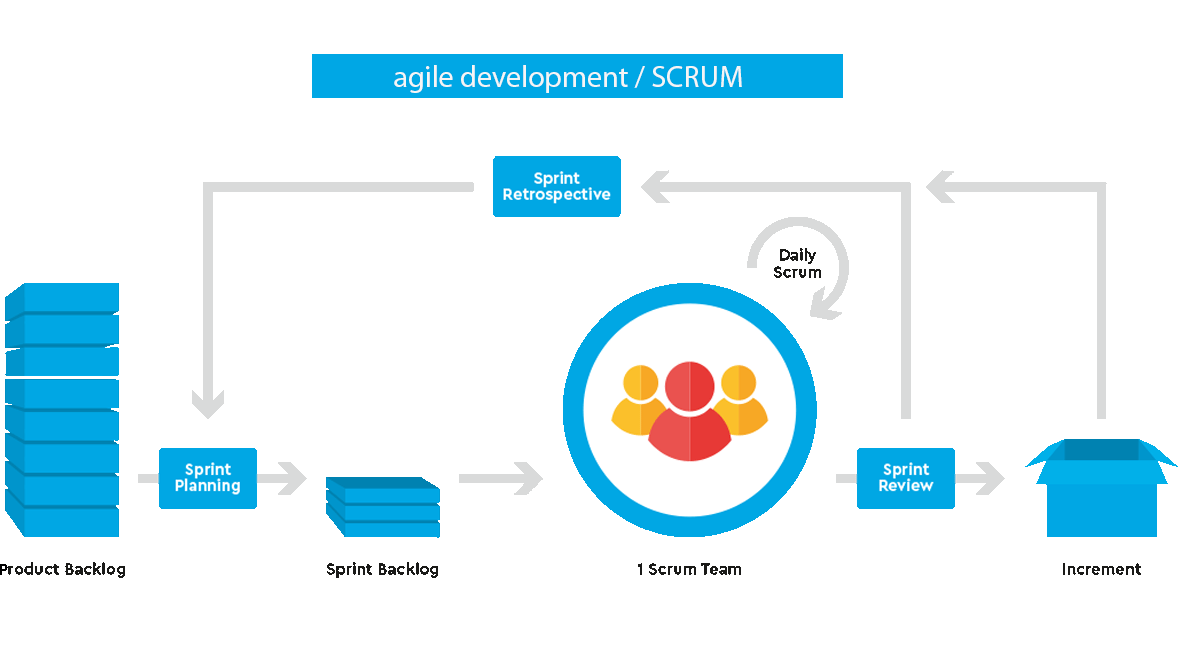

We develop complete products and systems for you according to your individual needs, from requirements engineering, electronics, software and mechanics development to product qualification and series transition.

Hardware development in the E²MS business: Depending on your requirements, we can provide support or take over the entire electronics development process for you, so that you can concentrate on your core competencies.

Microcontrollers – 8 to 64 bits, multicore und DSP – both modular and design-in solutions

Memory

Display und Touchscreens

Interfaces, field buses – offered as solution kits

Analogue technology, metrology

HF technology / radio technology

Power electronics / power supply

Optoelectronics, audio and video technology

Simulation

Motor controls

We support you with solutions tailored to your wishes, requirements and general framework. This ranges from hardware-related software components to complex application development, even in highly regulated environments (e.g. aviation, medical devices, and functionally safe systems). Everything is available as individual components or as complete systems. We enable short development times thanks to a large portfolio of existing and proven solution modules, thus offering quality and reliability.

Mikrocontroller Software

Application Development

Mobile Apps for iOS and Android

IoT, Web and Cloud Applications

Embedded Operating Systems

Engineering Services

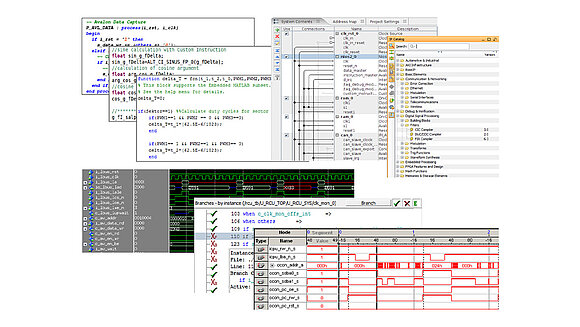

As an E²MS system supplier, TQ offers system-on-chip development, also known as Logic Design, of the highest quality.

SoC applications

Design service

SoC methodology

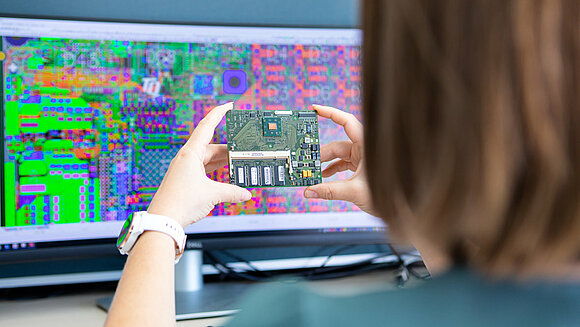

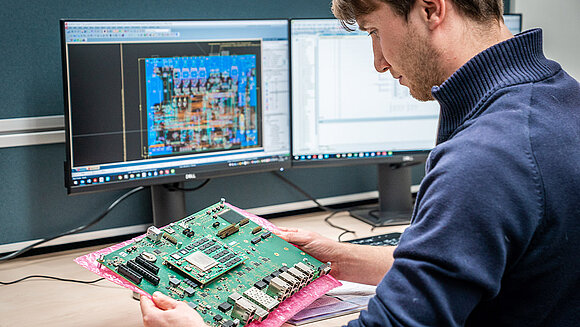

As an E²MS system supplier (E²MS = Electronic Engineering and Manufacturing Services), TQ can assist you at every stage of your project – according to your wishes and needs. In addition to electronics development, PCB layout (also called PCB design) including correct PCB realisation of challenging boards is a good entry point into TQ’s electronics services.

High PCB quality

Through intensive contact with various circuit board manufacturers qualified by TQ and the application of defined design rules, your circuit board is produced in a high-quality and cost-effective manner.

Design for Manufacturing (DFM), high assembly quality

With the help and feedback of TQ’s own assembly production department, we keep our PCB design rules up to date and place your components on your PCB in compliance with all electrical requirements.

Design for Testability (DFT), best possible testability of the printed board assembly

Test procedures are coordinated at an early stage with the TQ specialist department for test equipment development. This is how we achieve optimal test depth at low cost. The layout is designed for the most effective and cost-effective optical and electrical testing possible.

Rapid start of production

Internal review in the different design phases avoid the need for redesigns, saving you time and costs. Our overall view of your design across the entire process chain allows you to benefit from low product costs.

Our experienced development team designs and develops casings, drives and complete systems for you according to your requirements.

Range of services

Planning and conception

Design

Simulation

Connectors & Wiring

Sample and prototype construction

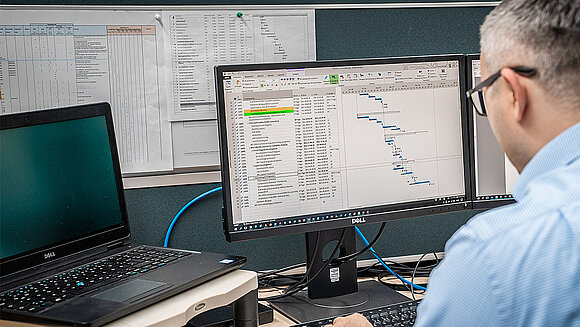

Benefit from the extensive experience and expertise and the support of our certified project managers for your products.

Scope of services

Methods

Tools

TQ offers a full range of services in the field of electromagnetic compatibility such as:

As an E²MS system supplier, the TQ-Group offers you a wide range of product tests at the highest level as a basis for product certifications and approvals:

Climate tests

Mechanical tests

EMC tests

Reliability and durability tests

More environmental tests

Radio approvals

Function and specification testing

Development process

Environmental protection requirements

Functional safety requirements

Other validation tests

Certifications and approvals

Product compliance tests, certifications and approvals at the TQ-Product-Compliance-Center

We plan, design and implement test equipment for assemblies and complete devices - optimally adapted to your respective requirements.

We ensure a fast and safe transition of your products into series production.