TQ-Aviation news

All news about TQ-Aviation, new products and services as well as press releases can be found in our news overview.

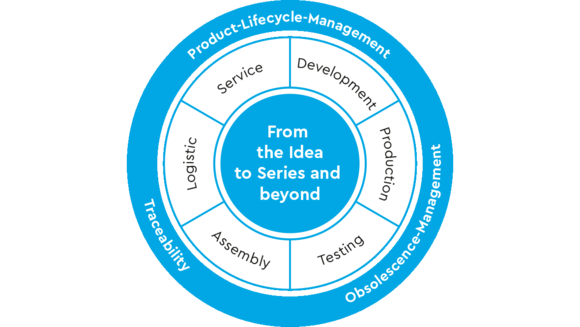

From idea to product service – we accompany, advise and guide you through the entire life cycle of your commercial aircraft products. Whether it is electronic assemblies or complete systems, we offer you all possible solutions to meet your requirements. You benefit from our many years of experience in the development of embedded systems, HMI systems, power electronics, drive technology, communication and radio technology as well as sophisticated industrial applications.

We stand for professionalism, reliability, product service and modular solutions in the international market.

All our aviation certificates can be found here.

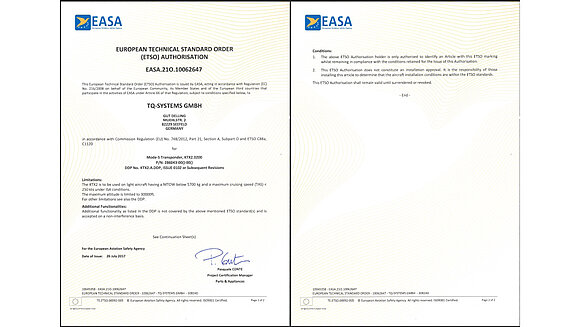

We collaborate with our customers to create the aviation products of tomorrow. TQ is certified according to EASA Design Organisation Part 21O and DIN EN 9100. We take care of the project from the initial idea to serial production.

Learn more about E²MS development

Customer-specific design and development:

Aviation standards

Boeing-specific standards

Product qualification and documentation

Airbus-specific standards

thanks to our many years of experience in contract manufacturing for industrial customers with medium batch sizes, we have developed into experts in the production of niche products. Optimal processes, state-of-the-art assembly automation and highly experienced, highly qualified personnel make our production process flexible and qualitatively very reliable. Our certification as an aviation manufacturer complements our expertise and enables us to meet the challenges of our customers. We manufacture on the basis of existing construction documents. It does not matter whether we have created the design for the customer or whether the customer provides the approved data!

PART 21 G, approved manufacturer

Learn more about E²MS Manufacturing

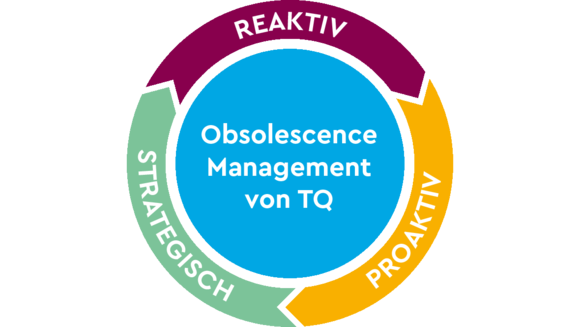

Especially in aviation, the long-term availability of materials and products plays a decisive role. TQ has been operating strategic obsolescence management for many years and has established a special team within the company dedicated exclusively to this topic.

We are ready to offer customer-specific service packages for your optimal product maintenance. Component discontinuations or other product improvements can be decisive. Please contact our team of experts. We are there for you at any time!

In addition to our successful (EASA) certification as an A-DOA development organization, TQ is also certified as both a Manufacturing Organization (Part 21G) as well as a Maintenance Organization (Part 145) for aviation technology by the Luftfahrt-Bundesamt (LBA)(the LBA is compareable to the FAA in the USA). TQ is one of the few E²MS service providers that combines all three of these important certifications. Hence, we can guarantee to fulfil our customers' needs around their electronic products, all from a single source.

The TQ-Group has expanded its industrial infrastructure internationally. Our plants in both Shanghai North America, function as satellites and thus enable us to offer our customers 24/7-support for AOG and spare parts management. By means of personal advice through our Field Application Engineers as well as FAQs and support wikis, we can help you with any challenge.

TQ is the right partner for you. In a risk-sharing partnership, TQ collaborates with you to implement your idea.

Development and production costs as well as product success are shared after successful market launch. Both parties pay in advance, while the compensation for both partners is achieved through the sales success. TQ will be happy to assist you.

A Partnership with TQ saves you valuable time and allows you to launch your product faster. Of course, you also benefit from the know-how of our entire development team. Whatever technology you want to use, TQ has certainly already developed an application that uses it. Whether aircraft cabin control, passenger service units or the various features of modern aircraft seats (USB power, in-flight entertainment and electrically adjustable seats) - in many cases, TQ is behind it all with their know-how and top product quality.

TQ supports the development, production and repair of equipment for the supply of "Cabin Power". These are in-seat power elements such as converters, sockets and cables which can be used both as stand-alone installations and for supplying IFE (In Flight Entertainment) systems.

The same applies to components for power management in the aircraft cabin. Power management is necessary for the secure operation of the power supply for all electronic installations in the passenger compartment, including the kitchens, toilets, seats and stairs. We are familiar with the entire topography/architecture of electronic systems in the aircraft cabin.

We are acquainted with the aviation-specific requirements for these systems and their components (approval, environment, safety).

Having been part of various customer projects from all industries and launched our own products in the areas of Drives, Medical and Embedded, we have gathered an enormous wealth of experience in handling active and passive displays (touch), which we install in products for the aircraft cabin crew as a user interface.

We can generate individual solutions for our customers from a construction kit.

We have many years of experience in the development, production and maintenance of components for the operation of electronically controlled aircraft cabin elements.

These include controls for lighting elements (signs, reading lights, etc.), passenger inputs (PAX call), display-based passenger advisories (e.g. no phoning, buckle up, no smoking), control elements for the crew communication system and cabin control functions, as well as all infrastructural components such as plugs, cables and installation aids.

We produce components and equipment for the electronic control of cargo/loading systems in the cargo sector for top-tier suppliers to the commercial aviation industry.

Our expertise in electronic drive technology for e-mobility and robodrives is the perfect basis for consulting, project planning, development and production of components for freight/loading systems.

We produce components and equipment for the electronic control of aircraft cabin modules such as kitchen functions, toilets, seats and seat-related installations for numerous top-tier suppliers to the aviation industry.