This service may collect data about your activities. Please inform yourself about the service and agree to the use of YouTube Video.

FAQ TQ-RoboDrive

In the following we have briefly and concisely summarized the answers to many frequently asked questions (FAQs). You will find them broken down according to topics and products.

If your question is not listed, please feel free to contact us directly at any time.

1. What is the difference between ILM "STD"- and ILM "HS" version?

The standard (STD) and high speed (HS) versions of our stators are different in the iron alloy and the thickness of the laminates. In the “HS” version we use an alloy, which reduces the dynamic losses at higher rotational speeds. This is possible by re-magnetization of the iron (hysteresis losses and eddy current losses). The datasheet is the same for both versions.

2. What are the primary differences between ILM-E and ILM frameless servo-kits?

The ILM-E is the logical development of the proven ILM series and was developed with the aim of offering a particularly attractive price-performance ratio. To achieve this, minor adjustments have been made to the design, resulting in only a minimal reduction in performance compared to the predecessor model.

The stators and rotors of both series are almost identical, so that both motor series can be interchanged without major design changes. Another difference lies in the installation method: the ILM stator is glued in the classic way, while the ILM-E stator is shrink-fitted into the housing.

The series also differ technically in terms of their structure: The ILM stator is encapsulated with epoxy resin, while the ILM-E has open, glued windings. In terms of sensor equipment, the ILM relies on optional THT Hall and temperature sensors, while the ILM-E uses SMD Hall and temperature sensors, which are integrated as standard in all models.

3. How are the ILM and ILM-E Servo-kits integrated?

The ILM stator is integrated into the housing by gluing while the ILM-E stator is shrink-fitted into the housing. The integration of the rotor, on the other hand, is the same for both ILM and ILM-E. They are both glued on to the shaft.

Take a look at the instructions from the TQ-ILM-E integration:

4. What category of motors do your frameless servo-kits belong to?

Our ILM and ILM-E Servo-kits belong to the category of permanent magnet synchronous motors (PMSM).

5. How is the rated voltage defined for your frameless servo-kits?

The rated voltage is a design criterion and is defined for 48 V (or 24 V for ILM25/38). Our motors meet all the requirements. Ex. “UL standards, EC guidelines and ISO DIN EN standards”.

6. How are the current values defined for your frameless servo-kits?

Our servo kits have a four-fold overload capacity with 20% linear saturation. The peak current is measured as the current at which the motor torque constantly drops by 20% of its ideal/theoretical value. If you divide this peak current value by 4, you get the rated current of the motor.

7. What is the relation between the motor torque constant and the back-EMF constant?

The motor torque constant kT [Nm/A] and the back-EMF constant kE [V/krpm] hold the following relation:

8. How does the induced voltage change with the idling speed?

The induced voltage varies linearly with the idling speed of the motor.

9. How can I calculate the motor electrical time constant?

The motor electrical time constant can be calculated by using the terminal resistance and terminal inductance values from the datasheet as follows:

10. How can I measure the motor rated speed from the T-N plot in the datasheets?

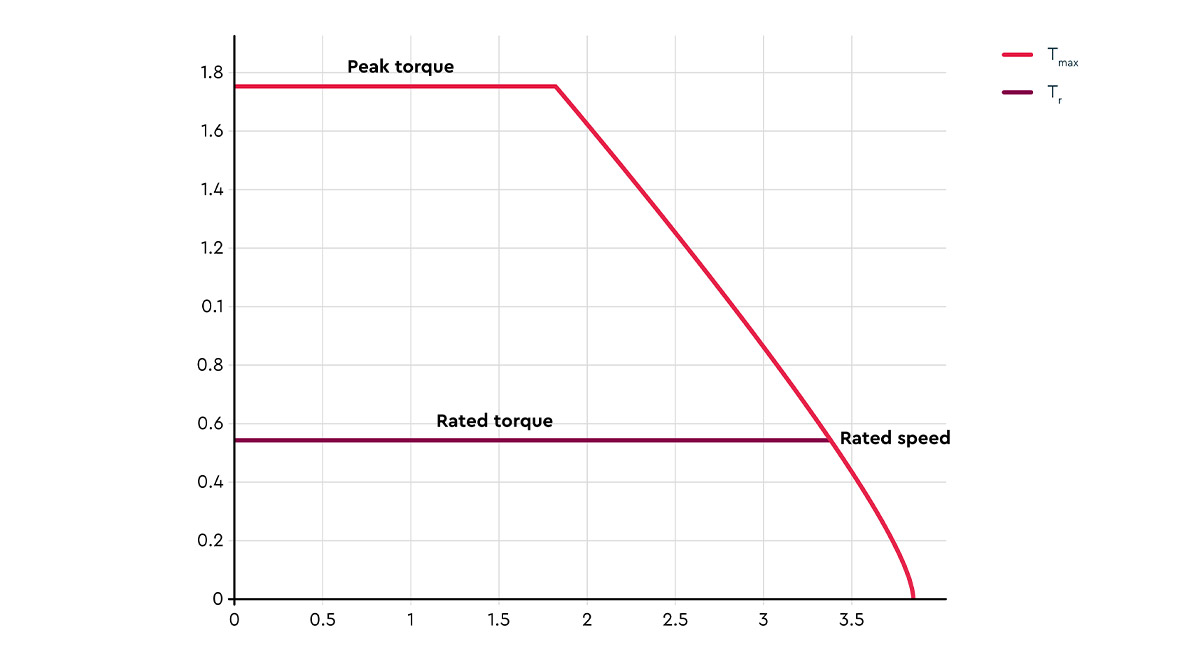

Our motors have only been measured for maximum idle speeds. However, one can determine the rated speed of our motor using the T-N diagram for a specific connection in the data sheet, as shown in the following picture:

11. What are the available stator-winding configurations for your frameless servo kits?

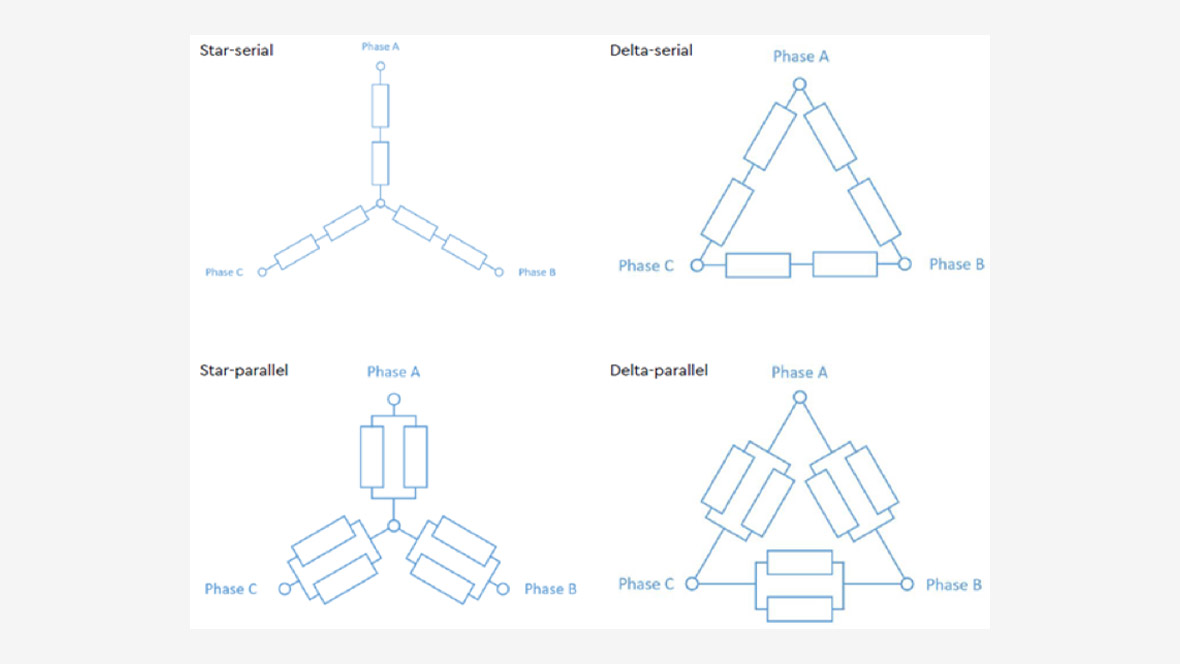

The variation in the stator-winding configuration comes from our interconnection PCB that is soldered to the 12 pins of the stator. We can offer the following interconnections for our servo kits:

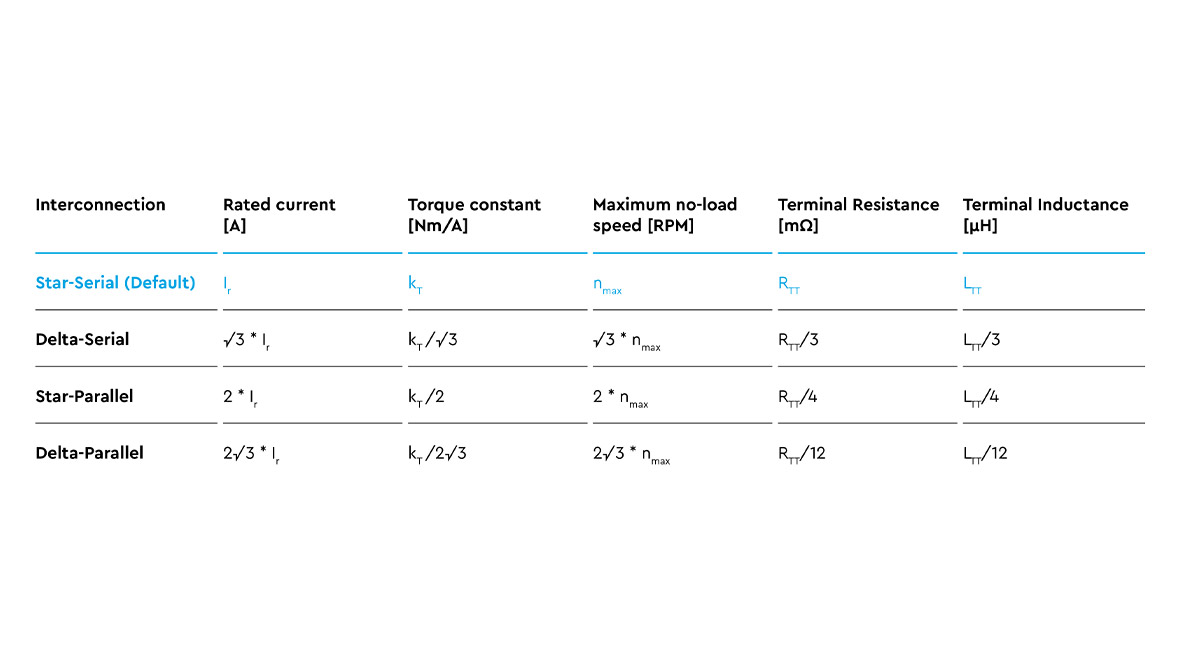

12. How does changing the winding interconnection influence the motor parameters?

For a given supply voltage, the rated and peak torques, copper losses and efficiency remains constant throughout all the interconnections.

The other parameters that change for all the available interconnections is presented in the table below:

13. Why is the motor torque constant not linear at peak torque?

According to our test bench measurements, the motor torque constant is not linear throughout the torque range but tends to go into a linear saturation of 20% at peak torque.

14. Is the rated current a peak value or an RMS value?

The rated current value is specified in our datasheet as peak value.

15. How does the motor performance vary with ambient temperature?

All our datasheet parameters were measured at a room temperature of 20-22°C. According to our S1 curves the ability of the motor to produce a continuous torque drops with increasing the ambient temperature. This point has to be considered while choosing a suitable motor size for the customer application.

16. How do your frameless servo-kits achieve such high torque density?

The main reasons for our industry leading torque density are:

- Very high copper fill factor through ortho-cyclic single-tooth winding

- Precise geometry of sheet metal cutting and the ratio of copper to Iron

- Good thermal connection of the stator to the housing by using a thermally conductive glue along with the vacuum potting of the stator windings

17. How are the copper losses calculated for frameless servo kits?

The copper losses are calculated during a steady-state operation by the formula:

18. What is the maximum operating temperature of your frameless servo kits?

The maximum operating temperature of our frameless servo-kits is 125 °C.

19. Do you also offer the servo kits with Hall and temperature sensors?

Yes, we offer Hall and temperature sensors. The ILM-E has Hall and temperature sensors as standard (see 2.). The Hall and temperature sensors are optional for ILM motors and can be installed upon request.

20. Why do I need a double rotor or an elongated rotor for the Hall version of an ILM servo kit?

The reason is that the Hall sensors are on top of the PCB. The normal stator is too short and so an extension is needed. Otherwise, the Hall sensor cannot detect the rotor position accurately.

21. What requirements does the inverter need to control the servo drive?

Our servo kits require a servo drive inverter that supports sinusoidal commutation and has a PWM frequency of more than 16 kHz.

22. Can you recommend a suitable servo drive inverter?

We recommend the servo drive inverters from Elmo Motion Control or Synapticon. The products of both companies work well with our motors.

23. What types of position encoders do you recommend?

We recommend the following two variants of position encoders:

1. Absolute AksIM encoders (Off-Axis Encoders) with BiSS-C protocol

2. Analog Sin/Cos encoders (On-Axis Encoders)