The path to perfect integration

Our white paper guides you step by step through all the relevant aspects:

- motor selection: What torque, what speed and what size does your application need?

- sensor technology: From encoder to torque sensor - which sensors ensure your precision?

- Gearbox: Direct drive or gearbox solution? When which technology makes sense.

- Motor controller: Selection criteria for performance, precision and safety.

- Integration: How to create the perfect mechanical, electrical and software connection between all components.

Find out how a frameless servomotor can be turned into a perfectly coordinated overall system. Our white paper shows you how to select the right components - from the motor to the controller - integrate them optimally and take your application to the next level. Whether robotics, medical technology or industrial automation: benefit from practical tips, technical insights and clear decision-making aids.

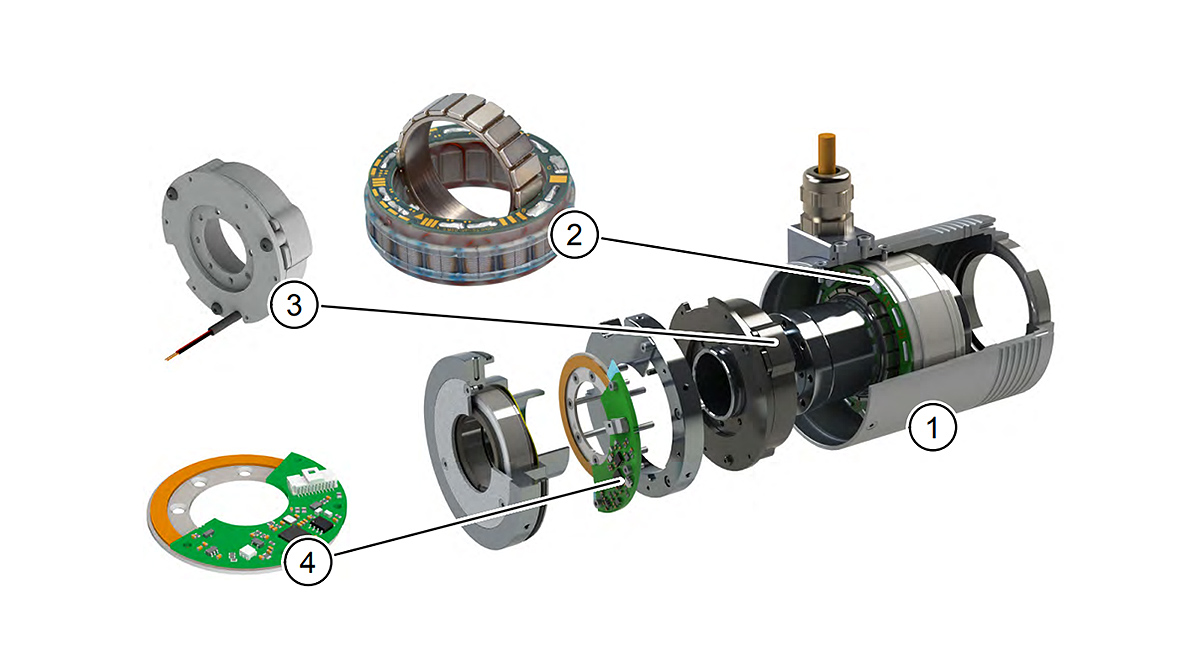

System components of a drive with hollow shaft motor

1. Hollow shaft motor with integrated safety brake

2. ILM servo kit

3. Safety brake

4. Absolute position sensor

Key questions before selecting the drive components:

- What power must the drive provide? (torque, speed)

- Which input variables are available? (Operating voltage, current, control interfaces)

- What other requirements must be met? (Weight, size, inertia)

- What are the requirements of the application? (Accuracy, speed, safety, braking)

Why torque motors from TQ?

- Maximum power density: Compact design for a lightweight, efficient system.

- High motor constant: Perfect for precise control in active and passive operation

- Easy integration: Ideal for seamless system adaptation in racing cars.

- Individual configuration options: Large selection of sizes & internal circuitry.